If you're looking for some inspiration about how to improve your branding and packaging,

these articles are just what the doctor ordered!

Articles on packaging and design

We enjoy working with

Let's talk

We would like to hear from you if you have any question or need a quote. Fill out this form and one of us will get it touch with your shortly.

“We nurture creativity in

every step of our

packaging production”

“We nurture creativity in

every step of our

packaging production”

Jan Kornelius, founding partner

Dive into our world

CREATIVE LAB

Design is key

Let us invite you into a world of

bold colours and patterns,

magnificent materials, innovative

designs and sustainable solutions.

CASES

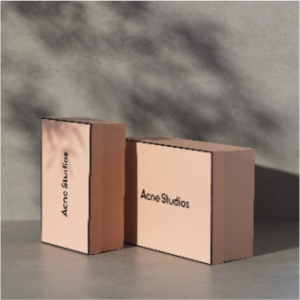

Patented peach and Japanese paper

ACNE Studio is an interesting

case of a fashion brand with

highs standards, a patented

Pantone colour, Japanese

custom made paper and a need

for sustainable solutions

CASES

We are only as good as our latest work

We love working with curious and ambitious

brands aiming to elevate the customer’s

experience.

Check out some of our work here and read more

about how we have helped elevate brands through

quality packaging solutions.

Get in touch

Super nerds and design passionates are ready to help you with your next-level packaging design. Just send us your contact info, and we will get in touch.

Get in the know

Subscribe to our newsletter. Stay up to date on the latest news, get discounts, and lots of inspiration.

Follow us

Hey! Are you following us on our socials? Click the links below to follow your favorites.

VAT no: DK71051218

Kratbjerg 308

3480 Fredensborg, Danmark

- +45 4824 2900

© 2022 Scanlux Packaging A/S